Assembling Products vs. Manufacturing: Pros, Cons, and Considerations

For Wholesale Distributors and other smaller companies that do not undertake a full-scale manufacturing operation, BIS offers some Assembly programs that are significantly easier for your staff to use and maintain at significantly lower costs. Often you acquire portions of a finished good you resell and assemble those parts to make a finished product.

That’s where BIS” Distribution application comes in quite handy.

Those parts or components become part of the Inventory being stocked and as you assemble those parts to make a finished product you resell, the individual parts are deducted and the finished good added to inventory stock levels. See below when the finished product M94 was produced and all the component parts that were utilized with appropriate costs were automatically deducted from their stock counts:

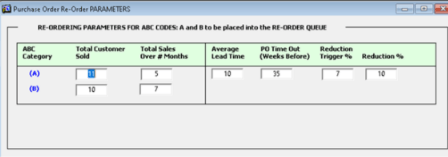

Knowing proper stock levels of parts that are used in a number of your finished goods sometimes can be difficult to forecast. The usage of those parts are utilized in the BIS Forecasting and Reorder modules to provide you with helpful data for your review. BIS has engaged experts in Forecasting and balancing proper stock levels based on the cost of carrying overstocks and lost sales. Look for our next blog which details this key area of your business.

Businesses often face a critical decision when it comes to producing goods: whether to assemble products or manufacture them from scratch. BIS Computer Solutions, a renowned company in the industry, understands the complexities involved in making this choice.

Assembling products can be a cost-effective and efficient way to bring goods to market, leveraging pre-made components. On the other hand, manufacturing offers control over the production process, potentially leading to higher quality and customization. Companies must weigh these options carefully, considering factors like production costs, product complexity, and market demand.

For businesses navigating these decisions, insights from experienced partners like BIS Computer Solutions can be invaluable. Their expertise in areas such as route accounting and warehouse management can help companies optimize their operations, whether they choose to assemble or manufacture.

Key Takeaways

- Assembling products can be more cost-effective than manufacturing.

- Manufacturing offers greater control over product quality and customization.

- BIS Computer Solutions provides valuable insights for businesses making this decision.

- Route accounting and warehouse management are crucial considerations.

- Companies must weigh production costs, product complexity, and market demand.

ASSEMBLYING PRODUCTS vs. the need for FULL BLOWN MANFACTURIING SYSTEMS a significant business decision

Deciding between assembling products and implementing full-blown manufacturing systems is a pivotal business decision that can significantly impact a company’s efficiency and bottom line. This choice is not just about production; it’s about aligning business operations with strategic goals, managing costs, and ensuring scalability.

What Defines Product Assembly Operations

Product assembly operations involve combining various components to create a final product. This process is often utilized by computer wholesale distributors in the USA who receive pre-manufactured parts and assemble them into finished goods. Assembly operations require specific tools, equipment, and skilled labor.

Full Manufacturing Systems Explained

Full manufacturing systems encompass the entire production process, from raw material sourcing to the final product. This comprehensive approach is often supported by trusted ERP systems that manage and integrate various aspects of the business. Full manufacturing allows for greater control over product quality and customization.

Core Differences in Approach, Infrastructure, and Investment

The core differences between product assembly and full manufacturing lie in their approach, infrastructure requirements, and investment needs. A comparison of these aspects is crucial for businesses to make informed decisions.

For businesses like BIS Computer Solutions, understanding these differences is key to making the right choice. Their expertise in ERP solutions and distribution management can guide companies in optimizing their operations, whether they choose product assembly or full manufacturing.

Comparative Analysis: Business Implications and Tradeoffs

Businesses considering whether to assemble products or manufacture them must navigate a complex landscape of costs, scalability, and quality control. This decision is crucial as it impacts their operational efficiency, cost structure, and ability to deliver products to the market.

Cost Considerations and ROI Expectations

The initial investment and ongoing costs associated with assembling products versus manufacturing them can vary significantly. Assembling products often requires less capital investment upfront, as it may involve less complex operations and lower costs for equipment and labor. In contrast, establishing a full-fledged manufacturing operation typically demands substantial investment in machinery, technology, and workforce training.

Return on Investment (ROI) expectations also differ between the two. Manufacturing operations, while costly to establish, can offer higher margins in the long run due to control over the production process and potentially lower costs per unit at scale. Assembling products, on the other hand, may offer quicker ROI due to lower initial costs, but the profit margins might be lower.

Scalability and Production Volume Capabilities

Scalability is another critical factor. Manufacturing operations are generally more scalable, as they involve controlling the production process from raw materials to finished goods. This control allows for more flexibility in scaling production up or down. Assembling products, while potentially less scalable, can still be adapted to changing demand through modular production systems.

“The key to scalability lies in the flexibility of your production system and your ability to adapt to changing market demands.” –

Industry Expert

Implementing cloud ERP solutions can significantly enhance scalability by providing real-time insights into production processes, enabling businesses to make informed decisions quickly.

Quality Control and Consistency Factors

Quality control is paramount in both assembling products and manufacturing. However, manufacturing allows for tighter control over the production process, potentially leading to higher consistency in product quality. Advanced manufacturing technologies, including automation and cybersecurity measures to protect against data breaches, play a crucial role in maintaining high-quality standards.

Time-to-Market and Supply Chain Flexibility

Time-to-marketing is a critical competitive factor. Assembling products can often be done more quickly than manufacturing, as it involves fewer production steps. However, managed IT services can help streamline both assembly and manufacturing processes by optimizing supply chain management and production planning.

Supply chain flexibility is also vital. Businesses that can adapt their supply chains quickly to changes in demand or supply disruptions are better positioned to maintain production and meet customer needs. This is where proactive monitoring and disaster recovery plans become essential, ensuring continuity of operations.

Conclusion: Making the Right Choice for Your Business

Deciding between assembling products and full-scale manufacturing is a critical business decision that hinges on several key factors, including cost considerations, scalability, quality control, and time-to-market. Businesses must weigh these elements carefully to determine the best approach for their operations.

Leveraging technology solutions such as Enterprise Resource Planning (ERP), warehouse management, and IT support services can significantly enhance operational efficiency. Companies like BIS Computer Solutions offer a range of services, including cloud services, network design, and business management software, that can support businesses in making informed decisions and optimizing their production processes.

By integrating solutions like inventory control, procurement software, and document & workflow management, businesses can streamline their operations, improve productivity, and reduce costs. Whether a company chooses to assemble products or invest in full manufacturing capabilities, the right technology and support can make a substantial difference in achieving success.

Ultimately, the key to making the right choice lies in understanding the specific needs of the business and aligning them with the most appropriate operational strategy, backed by robust technology and expert support.

FAQ

What is the main difference between assembling products and manufacturing?

Assembling products involves combining pre-made components into a final product, whereas manufacturing involves creating products from raw materials or components. Companies like BIS Computer Solutions can help businesses decide which approach is best for their operations.

How do I determine whether to invest in assembly operations or full-blown manufacturing systems?

To make this decision, consider factors such as production volume, scalability, quality control, and time-to-market. BIS Computer Solutions’ expertise in ERP solutions and distribution management can help businesses weigh these factors and make informed decisions.

What are the cost considerations for assembling products versus manufacturing?

Assembling products typically requires lower upfront costs compared to manufacturing, which involves investing in equipment, raw materials, and labor. However, the cost of components and labor can be added in assembly operations. Cloud ERP solutions can help businesses track and manage these costs.

How can I ensure quality control and consistency in my production process?

Implementing quality control measures, such as regular inspections and testing, can help ensure consistency in production. Managed IT services and cybersecurity can also play a role in protecting your production process from disruptions and cyber threats.

What role can technology solutions play in supporting my business decision?

Technology solutions such as ERP, warehouse management, and IT support services can help businesses streamline operations, improve efficiency, and reduce costs. Companies like BIS Computer Solutions offer a range of technological solutions to support businesses in making the right choice.

How can I scale my production to meet changing demand?

Scalability is a key consideration when deciding between assembling products and manufacturing. Businesses can use route accounting software and other distribution management tools to help scale their operations and meet changing demand.

What are the benefits of using cloud ERP solutions for my business?

Cloud ERP solutions offer flexibility, scalability, and cost savings, making it easier for businesses to manage operations and make informed decisions. BIS Computer Solutions can help businesses implement cloud ERP solutions tailored to their needs.